GERABODIES

ABOUT THE PROJECT

BACKGROUND

The success of the European rail system to foster the modal shift towards rail requires cost-efficient and reliable long-lasting trains. GEARBODIES contributes to this effort by improving the efficiency of rolling stock maintenance in close collaboration with the ongoing CFM-IP1-01-2019 (PIVOT2).

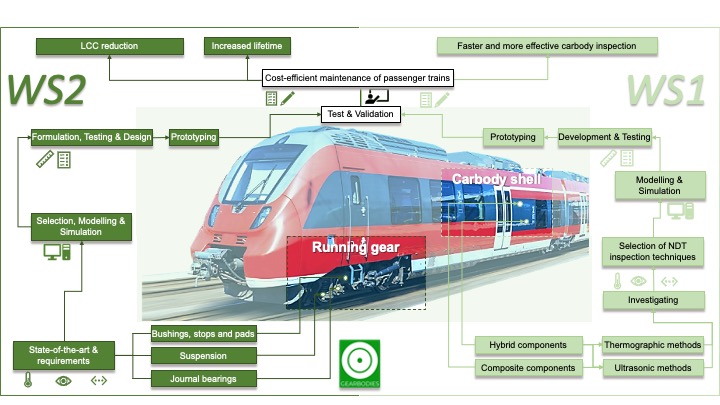

To achieve the above, GEARBODIES follows a twofold approach: extending overhaul periods and improving maintenance processes. The extension of overhaul periods will be facilitated by developing high-performance and long-lifetime components for running gear. The improvement of maintenance processes will be boosted by developing innovative NDT technologies to optimise inspection processes for lightweight carbody shells.

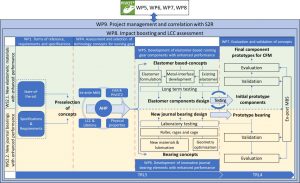

GEARBODIES will design and prototype several elastomer-metal running gear components, suitable for serial production, based on high-performance new elastomer formulations and existing elastomers not yet applied in rolling stock elements. In addition, the project will also explore innovative technologies for the development of low LCC bearings. New lubrication solutions, new materials for races and rollers, novel polymers for cages and the effects of new bearing geometries will be researched, among which the most feasible ones will be integrated in a new bearing design and prototyped.

GEARBODIES will develop an innovative modular platform to reduce the inspection time of lightweight carbody shells. The platform will incorporate tailored thermography and ultrasonic inspection systems and will facilitate the automated detection and assessment of defects throughout the thickness of the shell by using a customed software module.

GEARBODIES will benefit form a strong multidisciplinary consortium, made of 13 partners from 8 countries, committed to the mentioned actions towards maximisation of the project’s impact.